2026 JSRA British Jetsport Championship Seadoo Spark class

🎉 WIN A SURRON ULTRA MX BIKE! 🎉

Exclusive to 2026 British Jetsport Championship Seadoo Spark class riders only

The British Jetsport Championship has been generously gifted a brand-new 2026 Surron Ultra MX Bike — and one of you will be taking it home at the end of the 2026 season! 🔥🏁

How to Enter

✅ 1 raffle ticket for every round you race

(Compete in all 6 rounds = 6 chances to win)

✅ You must COMPLETE all motos at each round to qualify

✅ Raffle tickets are non-transferable

✅ You must attend the 2026 JSRA British Jetsport Championship Gala Presentation in November where the winner will be drawn live (if your not there you cannot win)

One of YOU will leave the Gala with a brand-new Surron Ultra MX…

Will it be you? 👀

#Surron #JetskiRacing #Mx #JSRA #BritishJetsportChampionship #BJC2026

Intended to promote interest in stock personal watercraft competition and to enable individuals to become active competitors with low investment and maintenance costs. The goal of Seadoo Spark racing is to have nearly identical characteristics to the watercraft that come off of the showroom floor with a focus on provisions for safety and handling in a competition environment. Watercraft competing in this class must conform to the specifications which follow which will be strictly interpreted.

To be eligible for the JSRA Seadoo Spark class the craft can be from any model of the Seadoo Spark range from 2014 to present, this includes 1up, 2up & 3up models and must be powered by the original equipment manufacturers naturally aspirated 3 cylinder four stoke Rotax 900cc Ace engine.

Below are the 2026 Seadoo Spark class competition rules

JSRA SPK.1 SEADOO SPARK CLASS COMPETITION

JSRA SPK.1.1 All watercraft must remain strictly stock, except where rules allow or require substitutions or modifications. Changes or modifications not listed here are not permitted. The JSRA may allow additional modifications to Stock Classified PWC which provide for replacement/reinforcements to parts and components (i.e, brackets, fittings, etc.) that have known failure risks in race conditions. Such changes will only be allowed if the replacements/modifications result in no volume or performance gains. Such allowances are only legal if published by the JSRA. Some original equipment components may not comply with JSRA rules. Hull Identification Numbers must be displayed as furnished by the manufacturer. NOTE: When rules permit or require equipment to be installed, replaced, altered or fabricated, it is the sole responsibility of the rider to select components, materials and/or fabricate the same so that the watercraft operates safely in competition.

JSRA SPK.1.2 Original equipment parts may be updated or backdated to original equipment parts of the same model. The part must be a bolt-on requiring no modifications to that part or any other parts except where rules allow substitutions or modifications. Unless reoffered to as the same identical part in the OEM parts/repair manual, parts may not be backdated.

JSRA SPK.1.3 Sound level shall not exceed 86 dB(a) at 22.86m (75 ft.).

JSRA SPK.1.4 Engine fuel must consist of un-leaded pump fuel

JSRA SPK.2 HULL

JSRA SPK.2.1 All watercraft must have a flexible tow loop attached to the bow. The tow loop should be made of a flexible material (e.g., nylon strap, rope, etc.) so as not to create a hazard. Tow hooks which protrude beyond the plane of the hull must be removed.

JSRA SPK.2.2 Hull and deck repairs may be made. However, these repairs must not alter the original configuration by more than 2.00mm (0.08 in.). The interior portion of a hull may not be reinforced. The texture of the exterior surface of the hull need not be consistent with OEM characteristics so long as the shape(s) remain exactly the same as OEM. Drop-in type storage buckets may be modified, aftermarket or removed provided a hazard is not created.

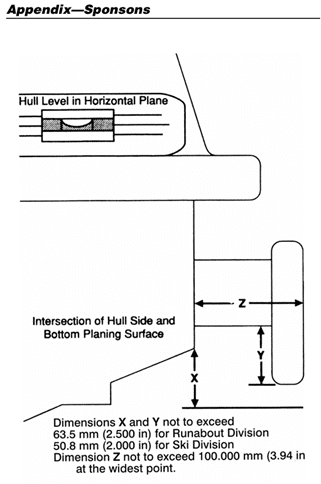

JSRA SPK.2.3 All watercraft may be equipped with a maximum of two sponsons. Original equipment sponsons may be modified, aftermarket, repositioned or removed. Overall length of each sponson shall not exceed 91.45cm (36.00 in.). Sponsons shall not protrude from the side of the hull by more than 100.00mm (3.94 in.) when measured in a level horizontal plane. The vertical channel created by the underside of the sponson shall not exceed 63.5mm (2.50in). No part of the sponson shall extend downward below the point at which the side of the hull intersects the bottom surface of the hull by more than 38.00mm (1.50 in.). Aftermarket or modified sponsons must exceed 6mm (0.24 in.) in thickness. All leading edges must be radiused so as not to create a hazard. Sponsons may not be attached to the planing surfaces of the hull. Fins, rudders, skegs and other appendages that may create a hazard will not be allowed. (See diagrams in Appendix.) The decision of the Technical Director and/or Race Director regarding modifications will be final. Any question regarding the legality of modifications should be directed to the JSRA prior to use in competition.

JSRA SPK.2.4 Intake grate may be modified or aftermarket. Intake grate is required and must be the full length type with at least one bar running parallel to the drive shaft. Grates may not extend more than 12.00mm (0.47 in.) below the flat plane of the pump intake area. All leading edges must be radiused so as not to create a hazard.

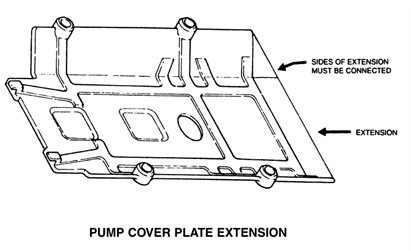

JSRA SPK.2.5 Pump cover plate may be modified or aftermarket. An extension may be added to the rear of the pump cover plate but shall not exceed the width of the original equipment plate. Modified and aftermarket plates must not extend more than 177.80mm (7.00 in.) beyond the end of the original equipment. The sides of the extension must be connected to the radiused portion of the pump plate so as not to create a hazard. Fins, rudders, skegs and other appendages must not create a hazard. (See diagram in Appendix.)

JSRA SPK.2.7 Replacement bumpers may be used provided a hazard is not created.

JSRA SPK.2.8 A soft, flexible water-spray deflector may be attached to the hull sides or to the bond flange provided a hazard is not created. No part of the deflector may extend beyond the perimeter of the original equipment bumper or side moldings as measured by a plumb line.

JSRA SPK.2.9 Handlebar, throttle, throttle cable, and grips may be modified or aftermarket. Handlebar cover may be modified or removed. Aftermarket switches and switch housings may be used. Steering shaft, steering shaft holder and handlebar holder may be aftermarket. The handlebar must be padded at the mounting bracket or, if it has a crossbar, the crossbar must be padded. Quick-turn steering modifications to alter steering ratio are allowed. Aftermarket steering cables will be allowed.

JSRA SPK.2.10 Original equipment seat base must be used. Seat cover may be changed. The OEM seat height cannot be changed by more than +/- 12.7mm (0.5 in). Seat must remain OEM; seat cover can add no more than 0.5 inch in thickness in any direction.

JSRA SPK.2.11 Padding and/or mat kits may be added and custom painting/graphics are allowed. The surface finish of any metal component outside the hull area above the bond flange may be polished, shot peened or painted.

JSRA SPK.2.12 Original bilge pump may be modified or disconnected. Aftermarket bilge draining systems that do not create a hazard are allowed.

JSRA SPK.2.13 Engine compartment ventilation tubes must remain as originally equipped.

JSRA SPK.2.14 Original equipment braking devices may be disabled for safety purposes. Reverse buckets may be removed or disabled (modified to disable reverse function is acceptable so long as a hazard is not created) but trim motors must remain in place.

JSRA SPK.2.15 The original equipment lanyard post may be protected or relocated from its original position so long as a hazard is not created.

JSRA SPK.2.16 Glove box lid may be removed.

JSRA SPK.2.17 The removable side access and top access panel(s) must be present and fitted.

JSRA SPK.2.18 Race numbers MUST be clearly visible and with the correct colour background for your skill and experience level. (please see the JSRA website post with regards to race numbers and colours)

JSRA SPK.3 ENGINE

JSRA SPK.3.1 Engines may be bored. Replacement piston assemblies may be used provided the original compression ratio, dome profile, skirt length and shape and type of material are not changed. Cylinder head combustion chambers may be cleaned by bead blasting with valves seated in place. Intake and exhaust ports may not be bead blasted or cleaned with abrasive material such as steel wool or Scotch-Brite®. Repairs to the cylinder head affecting one cylinder bank are allowed.

JSRA SPK.3.2 Repairs may be made to cracked or damaged cylinders by installing a cylinder sleeve. The head gasket surface of the cylinder block may be machined only to allow for the installation of the new sleeves (see appendix for description). A thicker head gasket must be utilized to return the block deck height to within .155mm (.006in) of original height. The repair must offer no additional performance gains.

JSRA SPK.3.3 Crankshaft must remain stock. Replacement bearings or bearing shells are allowed, providing they maintain their original type and dimensions.

JSRA SPK.3.4 Camshaft(s) must remain stock. Replacement bearings or bearing shells are allowed, providing they maintain their original type and dimensions. Camshaft timing may not be changed.

JSRA SPK.3.5 Engine and Oil Cooler watercooling systems must remain as OEM. Water strainers (filters) may be modified or aftermarket. Existing fittings may be aftermarket or modified so long as the OEM thread diameter is maintained. Fittings may not be added to the cylinder head, cylinder, or crankcase. Electronically controlled valves or water injections systems are not allowed unless originally equipped. Manually controlled devices (by any means of actuation) that alter the flow of cooling water during operation are not allowed. Cooling system flush kits are allowed.

JSRA SPK.3.6 Replacement of general maintenance parts (e.g., gaskets, seals, spark plugs, spark plug wires, spark plug caps, wiring, water hoses, fuel lines, clamps and fasteners) shall not be restricted to original equipment providing the following:

1) Replacement gaskets may be used but must be of the same type (e.g., sheet, o-ring, etc.) as their OEM counterparts. With the exception of head gasket, all replacement gaskets must maintain a thickness of plus or minus 20% of the OEM gasket thickness as furnished by the manufacturer. Head gaskets must be no thinner than .005mm (0.002in) than the OEM thickness as supplied by the manufacturer. Head gaskets must be no thicker than 1.55mm (0.06in) than the OEM thickness as supplied by the manufacturer.

2) Stripped threads must be repaired to the original size.

3) Fasteners (e.g., bolts, nuts and washers) may not be substituted with titanium pieces unless originally equipped. Fasteners may integrate locking mechanisms.

4) Replacement hoses and fuel lines may not provide any other function than original equipment hoses. Changes in temperature tolerances are allowed.

JSRA SPK.4 AIR/FUEL DELIVERY

JSRA SPK.4.1 Electronic fuel-injection systems: Flame arresters that meet USCG, UL-1111 or SAE J-1928 Marine backfire flame arrester test standards must be installed. If not equipped with an airflow sensor, the ducting between the flame arrester and throttle body may be modified or aftermarket. If originally equipped with an airflow sensor, the ducting may be modified or aftermarket between the flame arrestor and airflow sensor. Modifications to the airflow downstream of the airflow sensor are not allowed. All portions of the intake manifold must remain as originally equipped. Units where a ribbon system is employed as the OEM flame arresting device may have the ribbon removed so long as airflow is not increased and sufficient flame suppression is achieved by the air filter. An aftermarket part may be used to retain OEM airflow specifications.

JSRA SPK.4.3 Fuel injectors and fuel pump must remain stock as furnished by the manufacturer.

JSRA SPK.4.4 Crimped-type non-removable clamps must be used on the high-pressure portion of the system (i.e., worm type hose clamps, tie wraps, etc. are not allowed)

JSRA SPK.5 IGNITION AND ELECTRONICS

JSRA SPK.5.1 Replacement batteries are allowed but must fit into the original equipment battery box and be securely fastened.

JSRA SPK.5.2 The original electronic control unit may be reprogramed so long as it does not offer any additional inputs or outputs than the original unit, and it must connect with the original connections. No additional sensors may be added (e.g., exhaust gas temperature, detonation sensors, etc.). Engine temperature sensors may be disabled.

JSRA SPK.5.3 Aftermarket spark plugs with a different heat rating may be used.

JSRA SPK.6 DRIVELINE

JSRA SPK.6.1 Impeller may be modified or aftermarket, providing that the original diameter is maintained. Replacement wear rings that are within OEM internal diameter specifications may be used. Silicone adhesive sealant may be used in addition to original equipment seal to seal pump inlet.

JSRA SPK.6.2 Repairs to damaged pump stator veins will be allowed so long as the original vein profile/size/angle is maintained.

JSRA SPK.6.3 Pump shaft, bearings and seals maybe changed.

JSRA SPK.6.4 Reduction nozzle and steering nozzle must be un-modified and original with no modifications of any kind, including grinding, surfacing, polishing, machining, shot peening, etc., will be allowed on any driveline components with the exception of the pump stator following a repair (e.g., reduction nozzle, steering nozzle etc.).